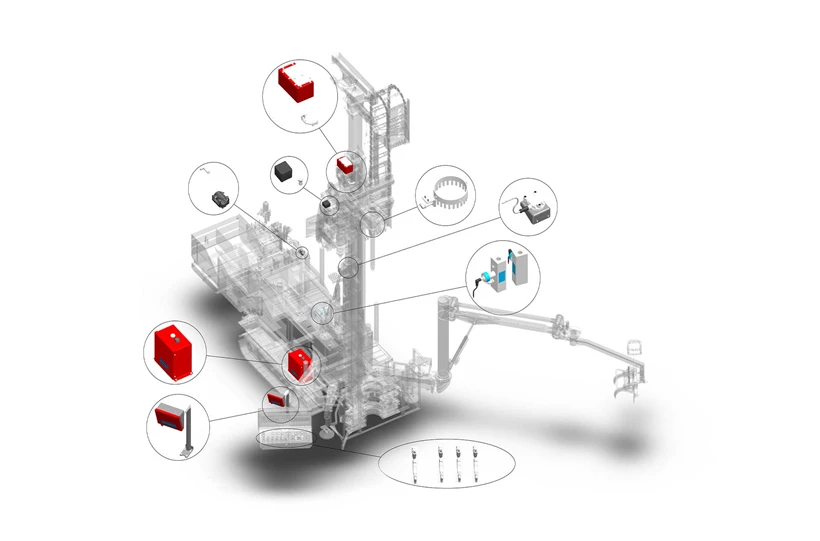

Manage your drilling campaigns efficiently and remotely with this 100% connected system. It consists of a set of sensors applied to your sonic drilling rig and a data platform to collect and review the data.

Discover the benefits of a specialised set of tools that collects real-time drilling data. It can help to bridge the gap between field crew and office, guide the drilling process, improve efficiency, and enhance safety.

Accomplish productive drilling campaigns with high efficiency through rig setting recommendations, automated operations and real-time insights on fleet performance, environmental footprint metrics and project (geological) information.

Benefits

Features:

Plan drilling campaigns

Through either an Excel file upload or manual input, drill campaigns and boreholes can be planned ahead right in the IoT data platform. The drill crew on site can access the list of planned boreholes through the touchscreen on the rig, find the nearest location through GPS and execute the borehole. Once finished, the status is automatically updated.

Monitor every step in the drilling process, on-site and remotely

The drill rig operator can monitor important drilling parameters through the touchscreen display, to adjust drill settings where necessary. The graphs are interactive and can be configured to show all relevant data, of the last 5 metres drilled. The touchscreen was designed to be used whilst wearing gloves.

Meanwhile, the project manager in the office can follow the process remotely and in real time* through the data platform, and is not required to physically visit the drill site.

*If the rig is currently in a location with 4G reception. If not, the system will store the data for transfer at a later time.

Export reports of drilling performance

While most monitoring systems display drilling data plotted against time, the Royal Eijkelkamp MWD system shows data related to depth. This provides other interesting insights. Reports can be configured to show specific data, such as fuel consumption or water usage. This helps to calculate the environmental footprint of a campaign. Reports even show the drilling process across projects.

| Filename |

|---|

| Brochure Monitoring While Drilling |